MSHA Assistant Secretary Williamson’s 2024 letter to the mining community

Dear Members of the Mining Community:

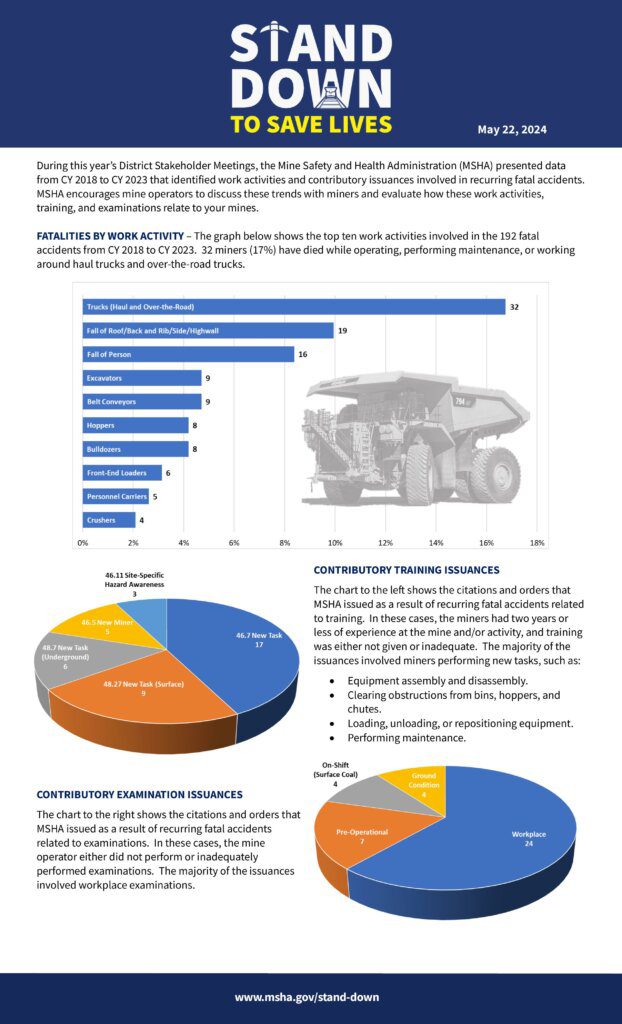

Last year, as the mining industry experienced a troubling increase in fatal accidents, I asked the mining community to join the Mine Safety and Health Administration in identifying and eliminating safety and health hazards that can cost miners their lives. As part of this effort, MSHA announced our first annual “Stand Down to Save Lives” and invited the mining community to join us in prioritizing miners’ safety and health. This year “Stand Down to Save Lives” will occur on May 22, 2024. We invite everyone to participate.

In the past year, I have traveled across the country, talking to miners and their representatives, operators, and safety professionals, and everyone I spoke with was troubled by last year’s fatality numbers. In those conversations there was broad agreement that the industry can and must do better. I write now to share that because of the collective efforts of the entire mining community, 12 fewer miners have died in workplace accidents this year compared to May last year. Although this progress is encouraging, even one miner fatality is still one too many.

I am asking the mining community to continue to work with MSHA and remain vigilant in focusing on identifying and eliminating hazards that can cause injuries and illnesses. For mine operators, it is critical to ensure that thorough and proper examinations are conducted to identify and eliminate hazards, and that all miners receive required and adequate training, including task training. MSHA also encourages miners to speak up and save lives by exercising their rights, playing an active role in safety and health, and using their voice to ensure safety and health is prioritized for themselves and their coworkers.

At MSHA, we will continue to use all our tools, including education and compliance assistance, sharing safety and health alerts and other information through our Miner Safety and Health mobile app, grants, and appropriate enforcement when necessary to hold operators, contractors, and individuals accountable. Recently, MSHA also finalized two rules that will save miners’ lives: Safety Program: Surface Mobile Equipment and Lowering Miners’ Exposure to Respirable Crystalline Silica and Improving Respiratory Protection. We will continue to actively engage with the mining community to ensure both rules are successfully implemented.

We encourage everyone in the mining community to join MSHA and Stand Down on May 22 to prioritize the safety and health of our nation’s miners. MSHA will share an online tool kit and resources and would appreciate you amplifying our message.

As we have learned throughout the years, we succeed when we work together, and miners are safer and healthier as a result. Together we have made a difference this year and thank you for your efforts. But there is still more work we must do to protect the miners that we care for and appreciate so much.

Sincerely,

Christopher J. Williamson

Assistant Secretary of Labor for

Mine Safety and Health

Purpose of the Event

The primary goal of Stand Down to Save Lives is to ensure everyone in the mining community takes steps to prevent fatalities – a robust safety and health culture should be in place not only on May 22nd but every day. This event is an opportunity for the entire mining community to:

- Engage in open discussions about prevalent hazards in the mining environment.

- Conduct thorough and detailed examinations of workplaces and equipment.

- Participate in safety training sessions designed to enhance awareness and preparedness.

The Stand Down is not just about taking a pause — it’s about taking action. We aim to empower every participant with the knowledge and tools needed to identify and mitigate risks, ensuring that every miner returns home safely at the end of the day.

Join Us

We encourage every member of the mining community to participate in this essential initiative. Together, through education, collaboration, and commitment to safety, we can significantly reduce the risks faced by our miners and work towards a future where every miner is safe, healthy, and secure.

Tell us about your Stand Down to Save Lives trainings and other events!

Remember: Safety is a shared responsibility. Let’s stand down to save lives.

You can view the full press release here.